We ensure excellence in the supply chain across the aviation, defense, and advanced technology sectors. Challenging factors such as excessive loads, harsh environmental conditions (contamination, extreme temperatures, pressure, etc.), and unique geometries do not limit us. We push the boundaries to deliver the most suitable products for your systems—without compromise. We address these challenges with the right material selection and high-quality bearings manufactured using advanced technologies. In short, we are your solution partner, offering tailor-made bearing services and technical support. Our goal is to produce our high-precision technologies—of national significance—100% domestically.

Precision Thin-Section Bearings by AKAR AKAR offers high-performance thin-section bearing solutions for applications with space or weight limitations. Our European and American-origin products come in 8 standard cross-sections and are available in ABEC 1 to ABEC 5 classes. Bearing types include C-Type (Radial), A-Type (Angular Contact), X-Type (Four-Point Contact), and B-Type (Duplex/Super Duplex). We also provide friction torque analysis, precise preload calculation, and full customization to meet specific application needs. AKAR – Precision and Reliability in Every Rotation

Miniature Bearings – One of AKAR’s Core Specialties Miniature bearings are undoubtedly one of AKAR’s key areas of expertise. Despite their small size, these bearings deliver a significant impact, making them a uniquely valuable product group. Our standard miniature range, sourced from AS9100D-certified manufacturers in Germany and Japan, exceeds industry standards with an operating temperature range of -50°C to +150°C. With precision levels up to ABEC 9P, customizable internal clearances (axial and radial), special shielding options, speeds exceeding 500,000 RPM, and even gold-plated finishes, this product group stands out for its exceptional versatility and performance.

KAR – Over 15 Years of Expertise in Linear Motion Systems For more than 15 years, AKAR has specialized in the supply of high-precision linear motion systems. We work closely with top-tier Japanese manufacturers—the industry's gold standard—as well as flexible Far Eastern producers who can meet even the most specific and complex requirements. Our product range includes: Precision Miniature Ball Screws (Trunnion type, Coated, Pitch >1mm) Miniature Rail & Block Systems (SRS, RSR Series) Slide Guides (VR-SV Series) Crossed Roller Bearings (RU, RA, RB Series) We offer full customization across all groups, including internal clearance, special coatings, and tailored lubrication solutions.

As the name suggests, Aerospace Control Bearings are essential components specifically manufactured for aerospace applications. These bearings are produced in compliance with various standards set by different institutions, such as SAE AS7949 (formerly MIL-B-7949), and are in high demand in the global aerospace market. The commonly stocked types include: B500 / MB500DD Series (MS27646, MS21428) KP / MKP / AMKP Series (MS27640, MS27640R) KP-A / MKP-A Series (MS27641, MS27641R) DPP / MDPP Series (MS27644) AW-AK Series (MS27649) ...and many more.

AKAR specializes in Spherical Bearings that are accredited to global standards and specifically developed for the defense and aerospace sectors. These bearings not only offer high load capacity, but also deliver exceptional performance under radial, axial, and combined loads. In addition to coordinating new series production, our extensive global aerospace network enables access to international inventories. We are also able to resolve urgent demands through partnerships with aerospace companies and government surplus stock sources. Frequently handled product types include: M81935 / M81936 Series (AS81935, AS81936) MS14101 / MS14104 Series (AS81820) EN4613 Series ...and many more.

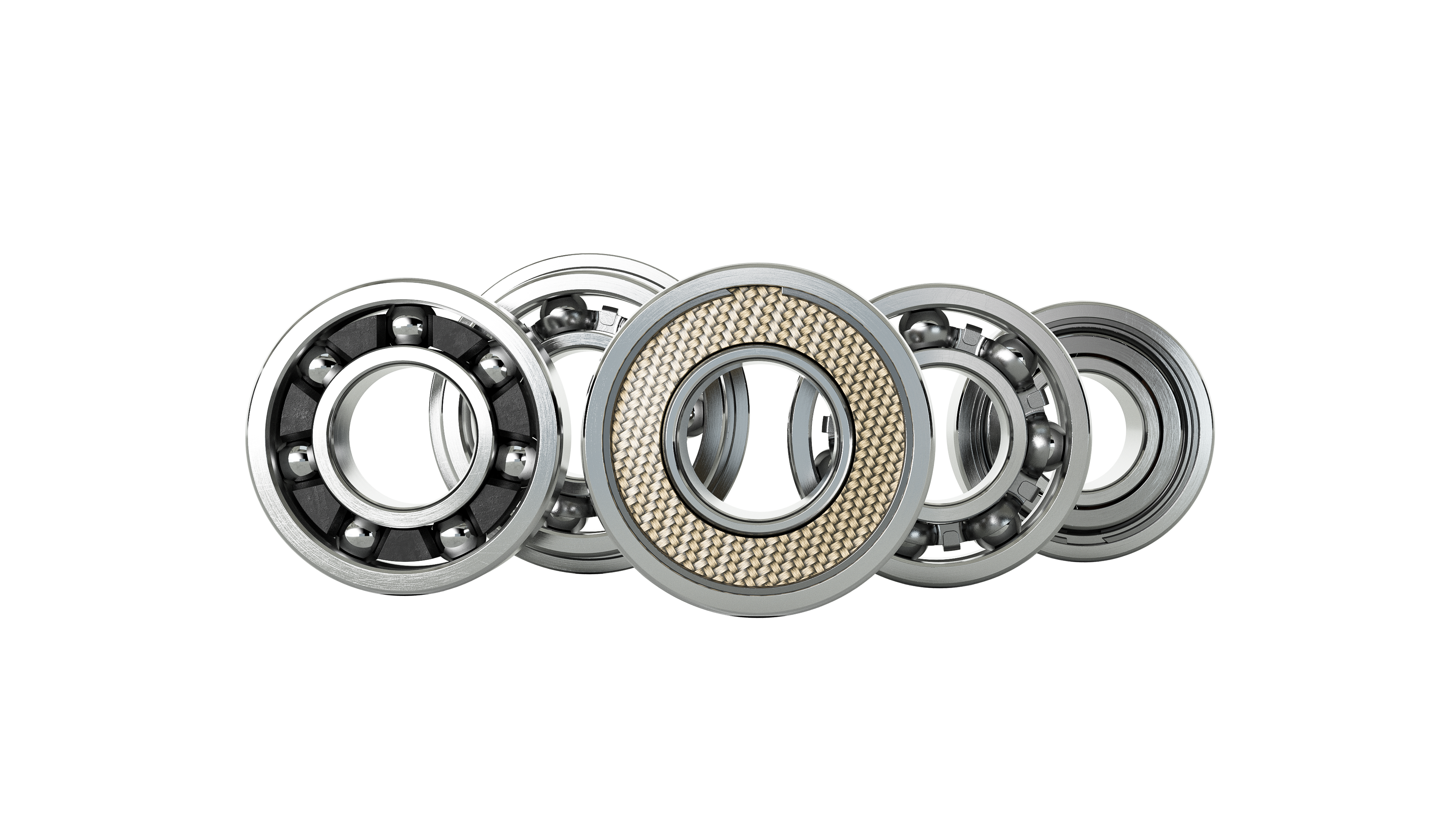

No matter the main category, standard materials, geometries, or features may not always meet the specific needs of your application. In some cases, a completely custom-designed product may be necessary. That’s exactly where AKAR steps in — no matter how challenging the requirements, we provide the right solution tailored to your needs. Common Requirements We Encounter: Insufficient (-/+) operating temperature range Equivalent load capacity with stainless or coated materials instead of chrome steel (52100) (e.g., M50, 17-4PH) Aerospace-grade heat treatment certifications Special contact angles Custom ball requirements (e.g., Si₃N₄, ZrO₂) Custom cage materials (e.g., PEEK, PTFE toroid, PA66)

Self-lubricating bushings maintain component alignment and ensure accurate motion. They tolerate high mechanical loads and provide extended service life with minimal wear. These bushings are effective in three systems: dry-running maintenance-free bearings, grease-lubricated low-maintenance bearings, and hydrodynamic principle-based bearings. In grease-lubricated types, initial grease is often sufficient for lifetime use; in harsh conditions, scheduled re-lubrication is advised to extend lifespan. Where oil or grease cannot be used, dry-running maintenance-free bushings are preferred. In such environments, special functional models or low-maintenance bushings are also suitable.

Needle Roller Bearings are used to reduce friction on surfaces that support rotational motion. Thanks to their long, thin rollers, they offer unique advantages to users. The wide surface area of these bearings remains in continuous contact with the roller raceways. While the core design of these bearings has remained largely unchanged for years, recent innovations have made updated versions more adaptable to the specific needs of engineers and designers. Whether as Needle Roller Bearings or simply Inner Rings, Akar Rulman, in partnership with RBC, is able to meet all of these requirements.

Wave washers and retaining rings are simple yet effective components that support Akar Rulman’s wide bearing range in terms of application and design. As the name "wave washer" suggests, these spring metal rings have a wavy shape. Their main function is to enhance the performance and efficiency of the bearings they accompany. With proper selection and installation, they help extend bearing life and improve load capacity. Additionally, they are highly effective as shock absorbers in space-constrained designs. As in many other product groups, Akar Rulman offers a wide variety of brands and provides custom production options alongside standard catalog items.

Spec Military Fasteners. Raw Materials. Steel (Alloy) Balls. We provide solutions for all your semi-finished product needs with options compliant with AMS, NAS, AS and other military-aerospace standards or standard industrial classifications. Fast solutions sourced from Europe, Turkey, USA, and the Far East, offering the right balance of price and performance.